Welcome to Vedarco, the European partner in precisions plastics manufacturing and engineering services that you can rely on.

We have our main office in United 27 Siddons Factory Howard Street Hill Top / West Bromwich B70 0SU Birmingham, England and we take pride in serving clients all over Europe with high-quality manufacturing solutions and a specialized product range for the food-processing industry.

Our Core Focus

Vedarco brings together technical skills, modern manufacturing technology and the reliability commitment.

The company operates in two fields that are distinct but complementary:

1. Precision Plastics Manufacturing & Engineering Services

This is the core of our business. We offer comprehensive, end-to-end services for the development of products made from plastic from idea to completion. Our skills involve:

- Design of the product and DFM (Design for Manufacture)

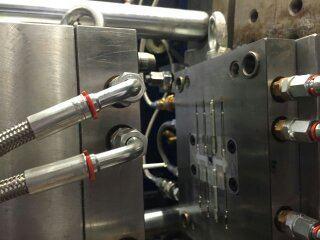

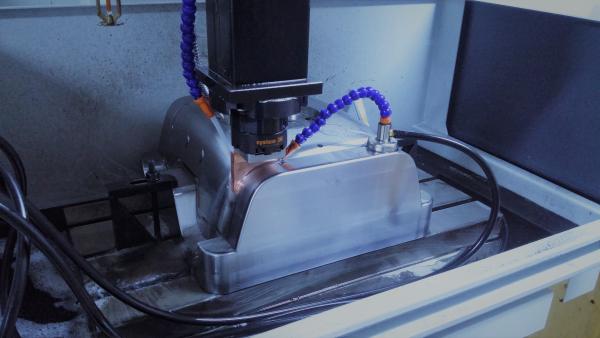

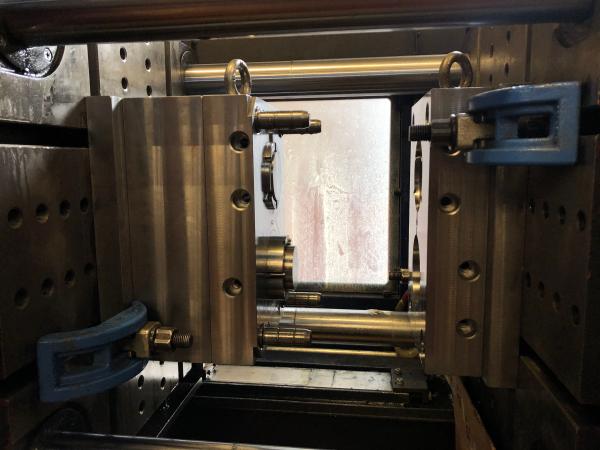

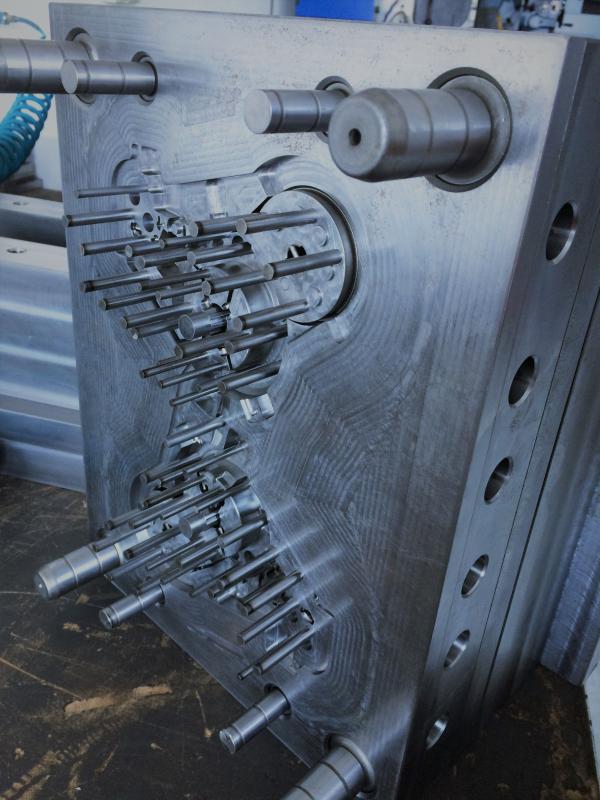

- Manufacturing of the moulds and production of tooling (steel or aluminium)

- Moulding by injecting for orders of low, medium, and high volume

- Operations of assembly, finishing, and value-added such as ultrasonic welding, laser marking, and custom packaging

Our clients come from a wide range of industries, industrial components and consumer goods to special technical products all getting the benefit of our responsive service, European reach, and consistent quality standards.

2. Meat-Processing Equipment & Weasand Clip Systems

Vedarco is not only a manufacturer but also a designer and supplier of hygienic processing equipment for meat industry. By means of our weasand clips, applicators, and sealing accessories, beef and sheep processors are able to perform their operations under hygienic conditions, which reduces the risk of contamination and consequently, the processors can operate safely and efficiently.

This range of products is an indication of our engineers’ accuracy and of the close ties we have maintained with the meat-processing plants in Europe over many decades.

Why Choose Vedarco

Dual expertise: We have combined the large-scale production capability of plastics with the supply of specialised solutions for food-processing applications.

European coverage: From our base in the UK, we provide our partners throughout Europe with flexible logistics and technical support.

Customised approach: A thorough understanding of the technical and operational requirements of the project guarantees its successful handling.

Quality and reliability: A strict process control and consistent standards are maintained, which in turn leads to dependable results every time.

Our Mission

We would like to be a partner, not merely a supplier — offering the precision, performance, and partnership that are the driving factors of our customers' success. Vedarco can always be counted on for innovation, consistency, and support across Europe regardless of whether complete plastics manufacturing solutions or reliable hygiene-control equipment for meat processing are required.

Hear From Our Customers

Feedback from the companies we work with. Discover their experiences and contact to discuss how we can support your next project.

They guided us through the tooling stage with patience and clear updates. The first production run went smoothly.