Reliable Solutions for Meat Processing Hygiene

We design practical, easy-to-use products that help reduce contamination risks during animal processing. Our goal is to support abattoirs of all sizes with safe and dependable solutions.

Bovine / Beef Ingesta Contamination Control

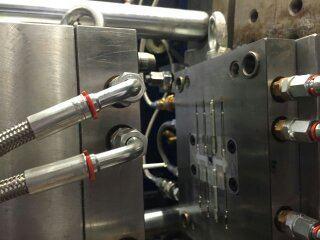

Discover our full range of specialised solutions for beef processing. From applicators and dispensers to reliable sealing tools, each product is designed to reduce contamination risk and improve workflow efficiency. Built for durability and ease of use, these tools have become essential for maintaining hygiene and quality in modern beef processing facilities.

Beef Weasand Clip Cartridge (For Dispensers)

Beef Rodding Tool

Ovine / Sheep Ingesta Contamination Control

Explore our complete line of products tailored for ovine processing. We offer advanced applicators, rodder tools, and secure sealing clips that simplify the handling of ingesta and protect against contamination. Trusted worldwide, these solutions combine speed, reliability, and food safety compliance, ensuring the highest standards are met throughout every stage of lamb and sheep processing.

Lamb Weasand Clip Loose

Lamb Weasand Clip Cartridge (For Dispensers)

Sheep Clip Rodder

Hear From Our Customers

Feedback from the companies we work with. Discover their experiences and contact to discuss how we can support your next project.

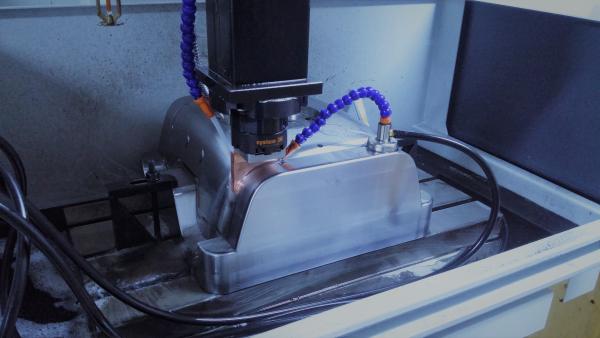

They guided us through the tooling stage with patience and clear updates. The first production run went smoothly.